A Ferrate Laboratory Treatability Test incorporates proprietary Ferrate (Iron VI) Treatment System chemistries into a bench test under controlled conditions that are designed to meet treatment objectives specified by the client.

The chemical modification or removal of target constituents is achieved by a combination of chemical reactions that can include oxidation, disinfection, complexation, or coagulation followed by the manipulation of one or more operational parameters such as pH adjustment, sedimentation, filtration and mixing.

Case Study 1

Objective

Disinfect for fecal coliform to meet high level disinfection standards for reclaimed water systems while remaining within total trihalomethane (TTHM) regulatory standards at a Southwest Florida Wastewater Plant.

Results

Several effluent samples were collected from the plant's treatment system. A Ferrate dose of as little as 1-ppm was effective in disinfecting for fecal coliform (FC) to the high-level regulatory limit of <1 CFU/100 mL.

A 2-ppm dose was equally effective for all the samples tested. This was achieved with minimal or no TTHM formation. Samples were also collected on different days to evaluate total phosphorus (TP) removal using Ferrate. A dose of 1-ppm reduced TP by 77% to 0.14 mg/L in one sample. Slightly higher dosages were even more effective in reducing TP to below 0.1 mg/L.

| Parameter | RAW | 1-ppm Ferrate | 2-ppm Ferrate | 3-ppm Ferrate |

|---|---|---|---|---|

|

Fecal Coliform - CFU/100 mL |

1,133.3 | <1 | <1 | N/A |

| TTHMs (ug/L) | U (.027) | I (0.31) | 0.60 | N/A |

| Fecal Coliform - CFU/100 mL |

200 | 68 | N/A | <1 |

| TTHMs (ug/L) | U (.037) | U (.037) | N/A | I (0.92) |

| Fecal Coliform - CFU/100 mL |

200 | 12 | N/A | <1 |

| TTHMs (ug/L) | U (.037) | U (.037) | N/A | I (0.94) |

- N/A = Not Analyzed

- U = Indicates that the compound was analyzed for but not detected.

- The Method Detection Limit is shown in parentheses.

- I = The reported value, shown in parentheses, is between the laboratory Method Detection Limit (MDL) and the Practical Quantitation Limit (PQL).

| Parameter | RAW | 1-ppm Ferrate | 3-ppm Ferrate | 5-ppm Ferrate |

|---|---|---|---|---|

| Total Phosphorus (mg/L) | 1.4 | 0.27 | 0.19 | 0.080 |

| Total Phosphorus (mg/L) | 0.79 | 0.50 | 0.15 | 0.064 |

| Total Phosphorus (mg/L) | 0.60 | 0.14 | I (0.025) | N/A |

| Total Phosphorus (mg/L) | 0.86 | 0.20 | .012 | N/A |

Case Study 2

Objective

Disinfect plant effluent for fecal coliform (FC) to <14 CFU/100 mL, and reduce CDBM (Dibromochloromethane), caused by chlorination of plant effluent, to below 34 ug/L at an East Coast Florida Wastewater Plant.

Results

At a dose of 3-ppm, not only was Ferrate Treatment able to meet the disinfection target, it also reduced the CDBM concentration down to 1.39 ug/L.

| Parameter | Chlorinated Plant Effluent | RAW Un-Chlorinated (Control) | 3-ppm Ferrate Dose | Reduction |

|---|---|---|---|---|

| CDBM | 123 ug/L | 0.88 ug/L | 1.39 ug/L | 99% |

| FC (CFU/100mL) | NA | 1857 | 3.7 | 3-log |

Case Study 3

Objective

To reduce extremely high color and disinfect for Total Coliform (TC) without exceeding regulated disinfection byproduct (DBP) standards at a Tennessee Wastewater Treatment Plant.

This facility's high effluent color is due in large part, but not exclusively, to a single industrial contributor.

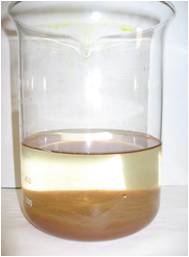

Results

Ferrate treatment at a dose of 15-ppm was able to reduce effluent color to 25 Platinum Cobalt Units (PtCoU), lower TC numbers to none detected (<1 CFU/100 mL), and to meet the DBP standards applicable to drinking water. Ferrate treatment at the same 15-ppm dose was still able to reduce effluent color to 25 PtCoU, even with this industrial source being contributed to the influent wastewater.

Effluent without Industrial contribution

Ferrate treatment at 15-ppm

| Sample | TC (CFU/100mL) | TTHM (ug/L) | HAA5 (ug/L) | Color (PtCoU) |

|---|---|---|---|---|

|

Raw Effluent w/o Industrial Contribution |

TNTC | 1.90 | 27.46 | >120 |

|

Treated Sample 15-ppm Ferrate |

<1 | 1.59 | 42.38 | 25 |

| Reduction | 99.99% | - | - | >79.17 |

| Raw Effluent with Industrial Contribution |

N/A | N/A | N/A | >120 |

|

Treated Sample 15-ppm Ferrate |

N/A | N/A | N/A | 25 |

- Total Trihalomethanes (TTHM) - Primary Drinking Water Standard <80 ug/L

- Haloacetic Acids (HAA5) - Primary Drinking Water Standard <60 ug/L

- TNTC = Too Numerous to Count

- N/A = Not Analyzed

Case Study 4

Objective

Achieve high-level disinfection of effluent (<1 CFU/100 mL), and meet primary drinking water DBP standards (TTHM and HAA5) at a Florida Wastewater Plant.

Samples were collected and tested from two points in the existing treatment train.

Results

The sample from the secondary clarifier was disinfected to the high-level standard using only 3-ppm of Ferrate. The disinfection byproducts were 1.11 ug/L of TTHM and 12.84 ug/L of HAA5, well below primary drinking water standards. An effluent sample collected after filtration was disinfected to the same standard using only 1-ppm of Ferrate. Analyses for DBPs were conducted using the 3-ppm Ferrate treated jar. The DBPs were 4.40 ug/L for TTHM and 18.80 ug/L for HAA5, well below primary drinking water standards.

| Secondary Clarifier | Coliform Bacteria per 100 mL | UV254 | TOC (mg/L) |

|---|---|---|---|

| Raw | 3,333.33 | NA | NA |

| 1-ppm Ferrate | <10 | NA | NA |

| 3-ppm Ferrate | <1 | 1.11 | 12.84 |

- Total Trihalomethanes (TTHM) - Primary Standard <80 ug/L

- Haloacetic Acids (HAA5) - Primary Standard <60 ug/L

- NA = Not Analyzed

| After Filtration | Coliform Bacteria per 100 mL | TTHM (ug/L ) | HAA5 (ug/L ) |

|---|---|---|---|

| Raw | 1,666.68 | NA | NA |

| 1-ppm Ferrate | <1 | NA | NA |

| 3-ppm Ferrate | <1 | 4.40 | 18.80 |