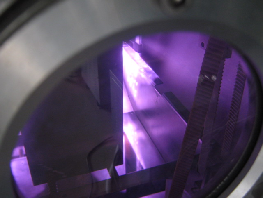

A Ferrate Laboratory Treatability Test incorporates proprietary Ferrate (Iron VI) Treatment System chemistries into a bench test under controlled conditions that are designed to meet treatment objectives specified by the client.

The chemical modification or removal of target constituents is achieved by a combination of chemical reactions that can include oxidation, disinfection, complexation, or coagulation followed by the manipulation of one or more operational parameters such as pH adjustment, sedimentation, filtration and mixing.

Case Study 1

Objective

Odor Removal at North Florida Drinking Water Treatment Plant

Results

A full scale Ferrate Treatment demonstration was conducted providing treated water for public consumption. Sulfide was reduced from an average concentration of 3 mg/l to below the laboratory detection limit of <0.010 mg/l by a Ferrate dose of 6 ppm.

A comparison of current operating costs showed that the cost of Ferrate Treatment is offset by replacing the existing chemicals used for treatment. Ferrate Treatment met or exceeded all performance expectations for sulfide removal and for treated water Disinfection By-Product (DBP) concentrations.

Case Study 2

Objective

Color and organics removal without formation of DBPs at a Florida Drinking Water Treatment Plant

Results

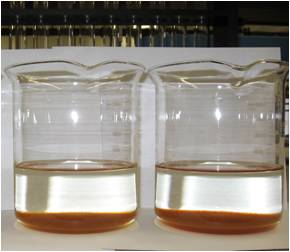

At a dose of 7-ppm, Ferrate treatment was able to reduce color by >87.5%, from >120 Platinum Cobalt Units (PtCo Units) in a blended raw water sample down to 15 PtCo Units. At a dose of 10-ppm, Ferrate treatment was able to reduce color by >91.7%, from >120 PtCo Units down to 10 PtCo Units.

In addition, the 7-ppm dose of Ferrate reduced Total Organic Carbon (TOC) by 70.1%, down from 14.4 mg/L in a blended raw water to 4.31 mg/L. Various forms of organics can act as precursors to the creation of disinfection byproducts. And the 10-ppm dose of Ferrate reduced TOC by 72.5%, down to 3.96 mg/L.

| Parameter | Blended Raw Sample (Control) | 7-ppm Ferrate Dose | Reduction | 10-ppm Ferrate Dose | Reduction |

|---|---|---|---|---|---|

| Color (PtCo Units) | >120 | 15 | >87.5% | 10 | >91.7% |

| TOC (mg/L) | 14.4 | 4.31 | 70.1% | 3.96 | 72.5% |

Blended (Raw Water)

Treated: 7-ppm Ferrate (left) - 10-ppm Ferrate (right)

Case Study 3

Objective

Replacement of ozone and reverse osmosis with Ferrate as a lower cost solution to reducing high color and iron levels as well as DBP precursors (UV254) from well water in a South Florida Drinking Water Treatment Plant

Results

At a Ferrate dose of 5-ppm, color was reduced by 91.7% from 120 PtCo Units to 10 PtCo Units. Iron was reduced by 98.5% from 4 mg/L to 0.06 mg/L. The same Ferrate dose lowered potential DBP precursor levels, as indicated by UV254, by 78.6% from an absorbance of 0.640 units down to 0.137 units.

| Parameter | Color Units | Iron (mg/L) | UV254 |

|---|---|---|---|

| Raw Sample (Control) | 120 | 4 | 0.640 |

| 5-ppm Ferrate (and FeCl3) | 10 | 0.06 | 0.137 |

| Percentage Reduction | 91.7% | 98.5% | 78.6% |

Raw Water Control

Water treated with 5-ppm Ferrate

Case Study 4

Objective

Removal of color, organics, and prevention of DBPs for an East Coast Florida surface water sourced Drinking Water Treatment Plant.

Results

A Ferrate dose of 5-ppm with a ferric chloride (FeCl3) dose of 13.5 mg/L reduced color from >240 units to <10, reduced UV254 by 91%, and reduced Total Organic Carbon by 75%.

This treated sample was then dosed with 4 mg/L chlorine and kept at room temperature for eight days to simulate the time water may remain in a distribution system, resulting in TTHM formation of only 0.3 ug/L and HAA5 formation of only 7.19 ug/L.

| Parameter | Color Unit | UV254 | TOC (mg/L) |

|---|---|---|---|

| Raw | >240 | 0.963 | 22 |

| 5-ppm Ferrate (and FeCl3) | <10 | 0.087 | 5.5 |

| Percentage Reduction | >96% | 91% | 75% |