Most Americans obtain their drinking water from public or private water systems that utilize surface water sources such as rivers, lake, reservoirs, or groundwater aquifers. The EPA regulates the quality of the nation's drinking water by issuing and enforcing safe drinking water standards. There are many contaminants that can be in the source water, and EPA regulations are becoming increasingly stringent as more is known about effect on public health.

In drinking water, Ferrate's powerful and unique chemistry can be used in the following applications:

- Color Removal

- Improvement of Taste & Odor Reduction

- Iron & Manganese Control

- Disinfection (Without Disinfection Byproducts)

- Destruction of Emerging Contaminants (ex. EDCs, PPCPs)

- Removal of Heavy Metals (ex. Arsenic, Chromium)

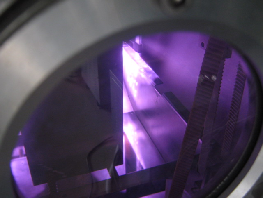

Certification Testing

The Model 100DW Ferrator has just passed NSF International Standard 61 Certification Testing for use in drinking water systems. It applies to both sodium and calcium Ferrate synthesized products when used at levels up to 50 parts Ferrate per million parts water.

What Does This Mean?

This Certification assures that there are no impurities imparted by our Ferrator to the Ferrate solution during synthesis. Hundreds of potential contaminants were submitted to analysis and review. All were below detectable levels and easily met Federal drinking water standards.

See for Yourself

You can view the NSF listing for the Ferrator on the Web at: http://www.nsf.org/Certified/PwsComponents/Listings.asp?Company=3H990&Standard=061.

What's Next?

Due to the certification, FTT can now actively deploy its Ferrator for drinking water applications throughout the U.S. and Canada. The Model 100DW Ferrator is an on-site generator of Ferrate that allows FTT to prove the power of Ferrate treatment by conducting continuous flow pilot and full-scale demonstrations at customer sites. We continue to receive inquiries from a growing list of municipalities and industries reaching out to discuss and experience the benefits of Ferrate at their facilities.

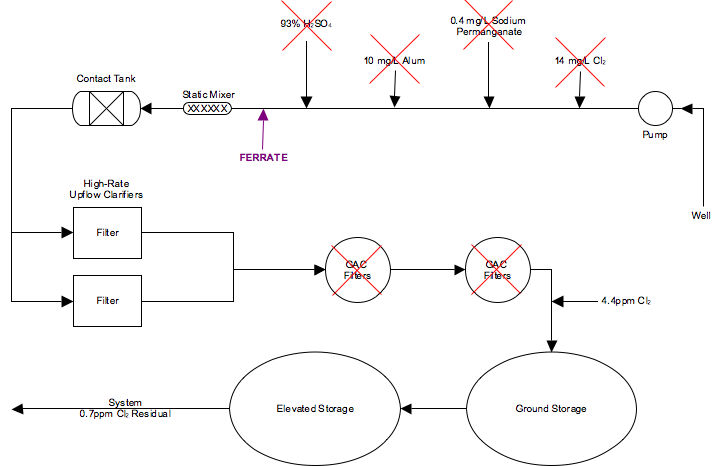

Example of Ferrate Treatment in A Drinking Water Plant

A Florida treatment plant is unable to meet their permit levels using their current treatment systems, and they have taste and odor problems. They are putting too many disinfectant byproducts into the water, and therefore, have to report it to their customers.

The following diagram shows how introducing Ferrate into the system can eliminate five of their current processes and save over 73% of their chemical costs every year. In addition, Ferrate was able to treat their water without introducing disinfectant byproducts, while eliminating taste and odor, and with a dose of less than five milligrams per liter (mg/L)!